The Secret to Delicious Low-Fat Products: Complete Guide to Whey Protein Micro-Particle Technology

Reducing fat in food products often results in a loss of creamy texture and mouthfeel. This comprehensive article explains how food science, particularly the process known as micro-particulation, can overcome this challenge and reproduce the sensation of fat without using actual fats. Here, we cover everything from scientific fundamentals to industrial applications, limitations, benefits, and how whey protein concentrate (WPC) can enhance the texture of low-fat products.

This guide is ideal for manufacturers, food formulators, nutrition professionals, and anyone interested in understanding modern techniques for improving the sensory experience of low-fat foods.

What You Will Learn in This Article

- What is Whey Protein and Why It Matters?

- Micro-Particle Technology — Science Behind Fat Simulation

- Technical Process: Heat Denaturation to High-Shear Homogenization

- Practical Applications in the Food Industry

- Benefits, Limitations, and Safety Considerations

- Formulation Tips for Manufacturers

- Frequently Asked Questions (FAQ)

- Conclusion and Future Outlook

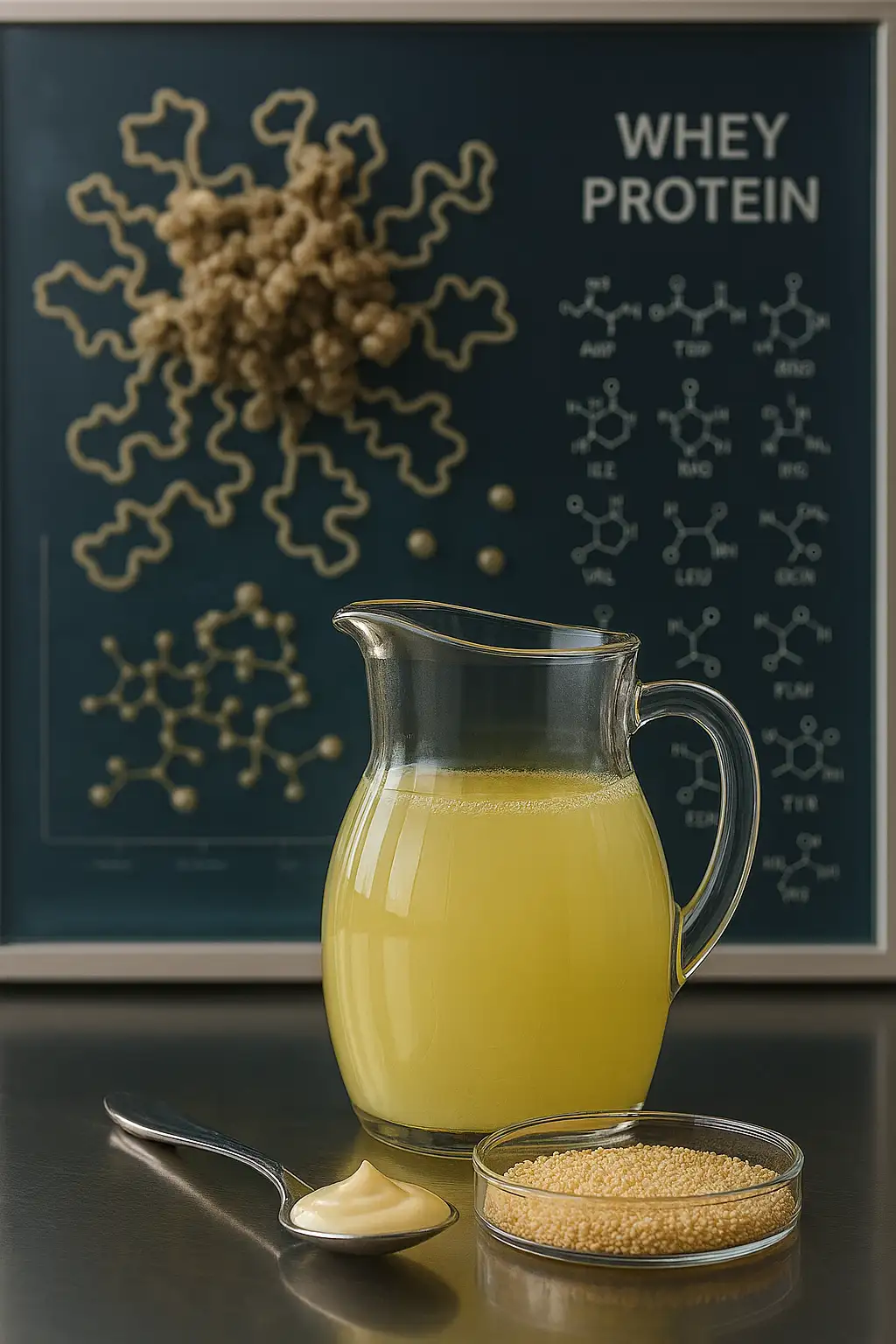

Hidden Hero: The Potential of Whey Protein

Whey is a liquid by-product of cheese production that contains highly digestible proteins with excellent nutritional value. In recent years, whey has transformed from a waste product into a valuable ingredient in the food industry. Whey proteins include both soluble caseins and whey proteins, rich in essential amino acids.

Using whey protein concentrate (WPC) in food formulations provides both nutritional and functional benefits: higher total protein content, improved texture, enhanced emulsification, and economic advantages by utilizing a by-product previously considered waste.

From a sustainability perspective, utilizing whey exemplifies a circular economy: converting waste into value-added materials reduces costs and environmental impact.

For more in-depth reading on whey protein processing, see our guide: Milk and Whey Fractionation – Advanced Dairy Processing Guide.

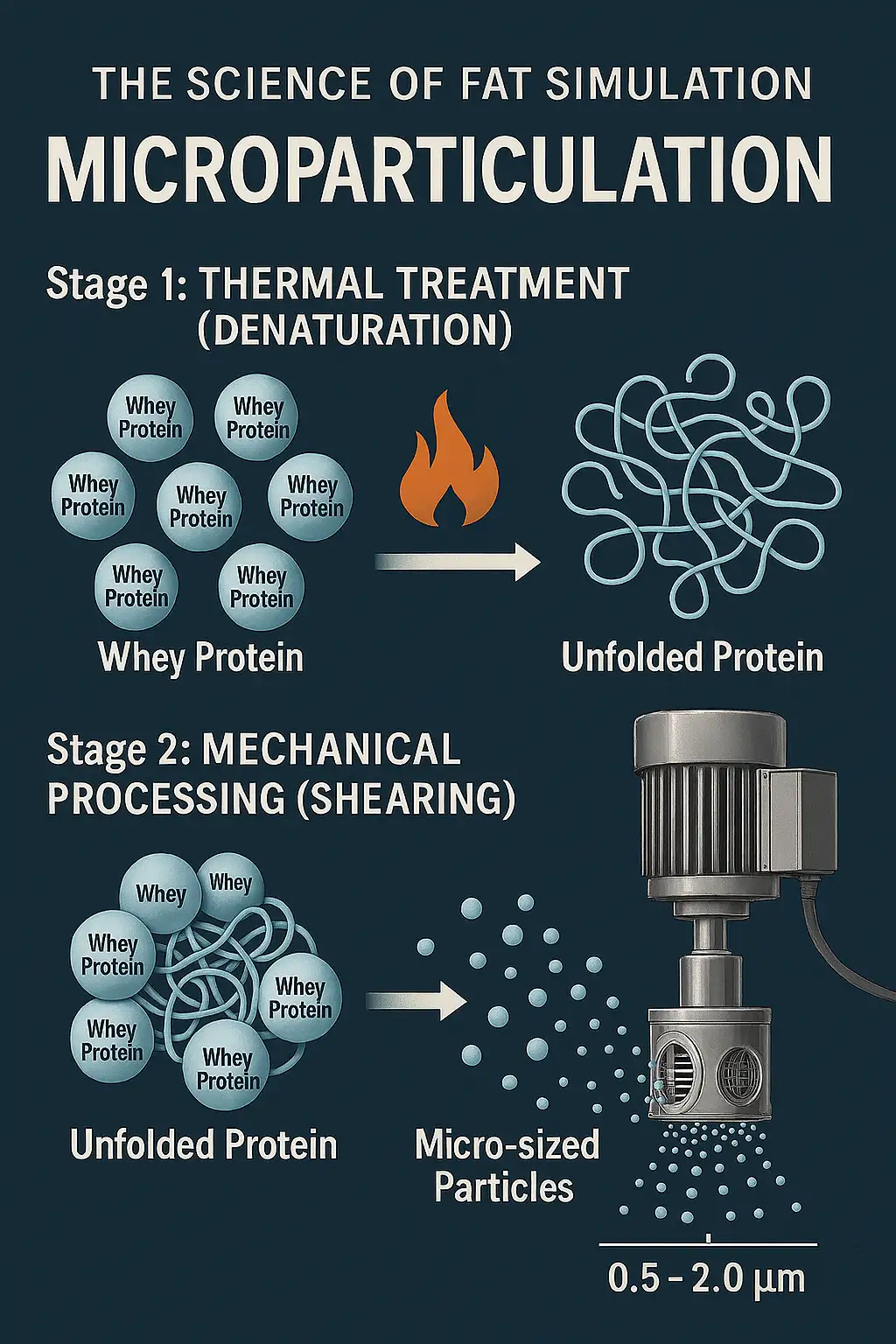

The Science of Fat Simulation: How Micro-Particles Fool the Palate

Fat mouthfeel is a complex sensory experience, combining lubrication, coating, and surface texture. Reproducing this sensation without real fat requires creating particles that mimic the behavior of fats when in contact with the tongue.

Micro-particulation is an engineered process that transforms soluble proteins, such as whey protein, into small, spherical particles with controlled sizes. These tiny particles glide across the tongue, producing the perception of creaminess without adding triglyceride fats.

For a more technical overview of whey powders and their types, benefits, and industrial applications, you can consult: What is Whey Powder: Benefits, Types, and Industrial Application.

Why Particle Size Matters

The size, shape, and distribution of particles determine the final sensory experience:

- Particles larger than 3 µm in aqueous suspension often feel powdery or sandy, which is undesirable for fat simulation.

- Particles smaller than ~0.5 µm may not provide sufficient lubrication to mimic fat.

- The ideal range for creating a creamy mouthfeel is approximately 0.5 to 2.0 µm. Precise control of thermal and mechanical processing is critical to achieve this distribution.

Without proper particle size control, the final product may have inconsistent texture or reduced stability.

From Lab to Production: Micro-Particle Process Steps

The transformation of whey protein into micro-particles involves a carefully controlled sequence of thermal and mechanical steps. These steps are critical for producing the desired creamy mouthfeel in low-fat products.

Step 1: Heat Denaturation

Whey protein solutions are exposed to controlled heat, which unfolds the compact, globular protein structure. This process is similar to unravelling a tightly wound ball of yarn. The exposed protein chains become reactive and ready for further mechanical processing.

Step 2: High-Shear Homogenization

Immediately after heat treatment, the unfolded proteins undergo intense mechanical shearing. High-pressure homogenizers are typically used to prevent aggregation and gel formation. The proteins are broken into uniform spherical micro-particles capable of sliding freely, creating the perception of fat in the mouth.

Critical Considerations

- Temperature control is essential: excessive heat can irreversibly denature proteins, destroying the micro-particle structure.

- Shear force must be optimized: insufficient shear results in larger, gritty particles, while excessive shear can damage particle integrity.

- Particle size distribution must remain within 0.5–2 µm for optimal creaminess.

Practical Applications of Whey Protein Micro-Particles

Micro-particulate whey protein opens doors to multiple low-fat and high-protein product innovations, offering both sensory and nutritional improvements.

1. Dairy Products

- Low-Fat Yogurt: Creates creamy texture without additional fats.

- Cheese: Enhances softness and prevents excessive hardness in varieties like cheddar or mozzarella.

- Ice Cream: Improves creaminess while reducing fat content and minimizing ice crystal formation.

2. Sauces and Dressings

- Supports emulsification in salad dressings and low-fat mayonnaise.

- Produces a smooth, rich texture similar to full-fat versions.

3. Other Applications

- Pastries and desserts: improves moisture retention and mouthfeel.

- Meat products: maintains juiciness and soft texture.

- Protein-enriched beverages and nutritional supplements.

For high-quality whey protein products suitable for these applications, see: Whey Protein Concentrate (WPC) or Whey Powder Supplier.

Limitations and Considerations

- Protein-based fat replacers like Simplesse cannot tolerate cooking above 100°C, limiting their use in frying or high-temperature baking.

- Processing complexity requires precise temperature and shear control for consistent particle size and sensory quality.

- Storage stability must be monitored, as improper handling can cause aggregation or phase separation.

Comprehensive Benefits of Whey Protein Micro-Particles

Beyond simulating fat, micro-particulated whey proteins provide multiple advantages for manufacturers, consumers, and the environment.

- Environmental Sustainability: Using whey, a by-product of cheese production, reduces waste and supports a circular economy in the dairy industry.

- Improved Product Quality: Micro-particles enhance texture, creaminess, and appearance, while also improving flavor perception.

- Increased Yield: Micro-particles improve water binding in formulations, leading to higher final product yield.

- Cost Efficiency: Replacing expensive fats with whey micro-particles can lower production costs.

- Added Nutritional Value: Provides high-quality protein, and residual lactose can act as a prebiotic, supporting gut health.

Formulation Tips for Manufacturers

- Maintain precise control over particle size (0.5–2 µm) for consistent creaminess.

- Combine whey protein micro-particles with other stabilizers for improved shelf-life.

- Carefully select applications suitable for low-heat processing to avoid denaturation.

- Use whey protein concentrate (WPC) for both functional and nutritional benefits in low-fat product formulations.

Frequently Asked Questions (FAQ)

- Can micro-particulated whey protein replace all fats? Not in high-heat cooking; it is best suited for low-fat yogurts, sauces, and cold applications.

- Is WPC safe for consumption? Yes, WPC is widely recognized as safe and nutritious.

- Does micro-particulation affect taste? When processed correctly, it enhances creaminess without altering the intended flavor.

Conclusion: The Future of Smart, Healthy Food

Micro-particulated whey protein demonstrates the power of modern food science to enhance low-fat products without sacrificing texture, creaminess, or nutrition. By transforming whey—a by-product of cheese production—into a high-value functional ingredient, manufacturers can deliver products that are healthier, more sustainable, and sensory-rich.

This technology represents a step forward in combining innovation, health, and environmental responsibility in the food industry. As research continues, we can expect further improvements and applications in both dairy and non-dairy products.